Continuously hot-dip coated steel

Hot-dip galvanized

Standard of reference EN 10346

Coating identification (Z)

Structural steel

| S220GD + Z | S250GD + Z | S280GD + Z |

| S320GD + Z | S350GD + Z | S550GD + Z |

Profiling and drawing steel

| DX51D + Z |

for profiling |

| DX52D + Z |

for light drawing |

| DX53D + Z |

for deep drawing |

| DX54D + Z | for very deep drawing |

| DX56D + Z | for extra deep drawing |

| DX57D + Z | for super deep drawing |

Zinc aluminium (Galfan)

Standard of reference EN 10346

Coating identification (ZA)

Structural steel

| S220GD + ZA | S250GD + ZA | S280GD + ZA |

| S320GD + ZA | S350GD + ZA | S550GD + ZA |

Profiling and drawing steel

| DX51D + ZA | for profiling |

|---|---|

| DX52D + ZA | for light drawing |

| DX53D + ZA | for deep drawing |

| DX54D + ZA | for very deep drawing |

| DX56D + ZA | for extra deep drawing |

| DX57D + ZA | for super deep drawing |

Aluminized

Standard of reference EN 10346

Coating identification (AS)

Structural steel

| S220GD + AS | S250GD + AS | S280GD + AS |

| S320GD + AS | S350GD + AS | S550GD + AS |

Profiling and drawing steel

| DX51D + AS | for profiling |

|---|---|

| DX52D + AS | for light drawing |

| DX53D + AS | for deep drawing |

| DX54D + AS | for very deep drawing |

| DX55D + AS | for deep drawing and high temperature |

| DX56D + AS | for extra deep drawing |

| DX57D + AS | for super deep drawing |

Aluzinc

Standard of reference EN 10346

Coating identification (AZ)

Structural steel

| S220GD + AZ | S250GD + AZ | S280GD + AZ |

| S320GD + AZ | S350GD + AZ | S550GD + AZ |

Profiling and drawing steel

| DX51D + AZ | for profiling |

|---|---|

| DX52D + AZ | for light drawing |

| DX53D + AZ | for deep drawing |

| DX54D + AZ | for very deep drawing |

| DX56D + AZ | for extra deep drawing |

| DX57D + AZ | for super deep drawing |

Electrogalvanized steel

Standard of reference EN 10152

Coating identification (ZE)

Electro-galvanised steels are electrolytically coated with zinc to obtain a product with the same characteristics of use of cold-rolled steels and at the same time have a greater protection against corrosion.

| DC01 + ZE | for profiling |

|---|---|

| DC03 + ZE | for light drawing |

| DC04 + ZE | for deep drawing |

| DC05 + ZE | for very deep drawing |

| DC06 + ZE | for extra deep drawing |

| DC07 + ZE | for super deep drawing |

Zinc magnesium

Corrender is the intuition which extends the life of coated steel!

Specific stress tests have shown that the zinc-magnesium layer protect against water, ammonia, chlorine, weathering and more than the classical zinc coating therefore improving pressing and painting characteristics too!tura.

High corrosion-resistant zinc-magnesium coated steel (Corrender)

Product description:

What is zinc magnesium?

Zn alloy +1,5% Mg + 2% Al (average values)

Protection:

The layer of coating, which has formed, delays the development of corrosion.

This results in a reduction of the thickness of the zinc and better anti-corrosion protection.

Product characteristics:

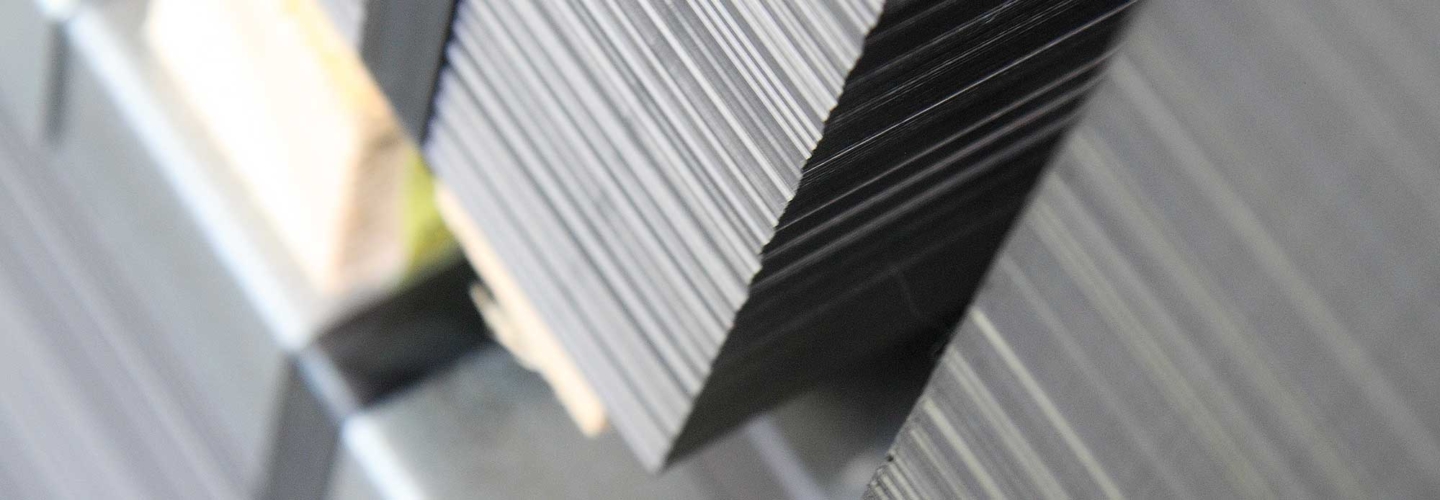

Better anti-corrosion protection (a formation time of rust greater by 5 times was observed)

Superior scratch resistance (hardness is two times greater)

Workability: excellent adhesion of layer of zinc-magnesium coating (particles do not detach)

Improved adhesion of painting

Welding: there are no notable advantages – the only noteworthy fact is that there is less coating so welding is easier

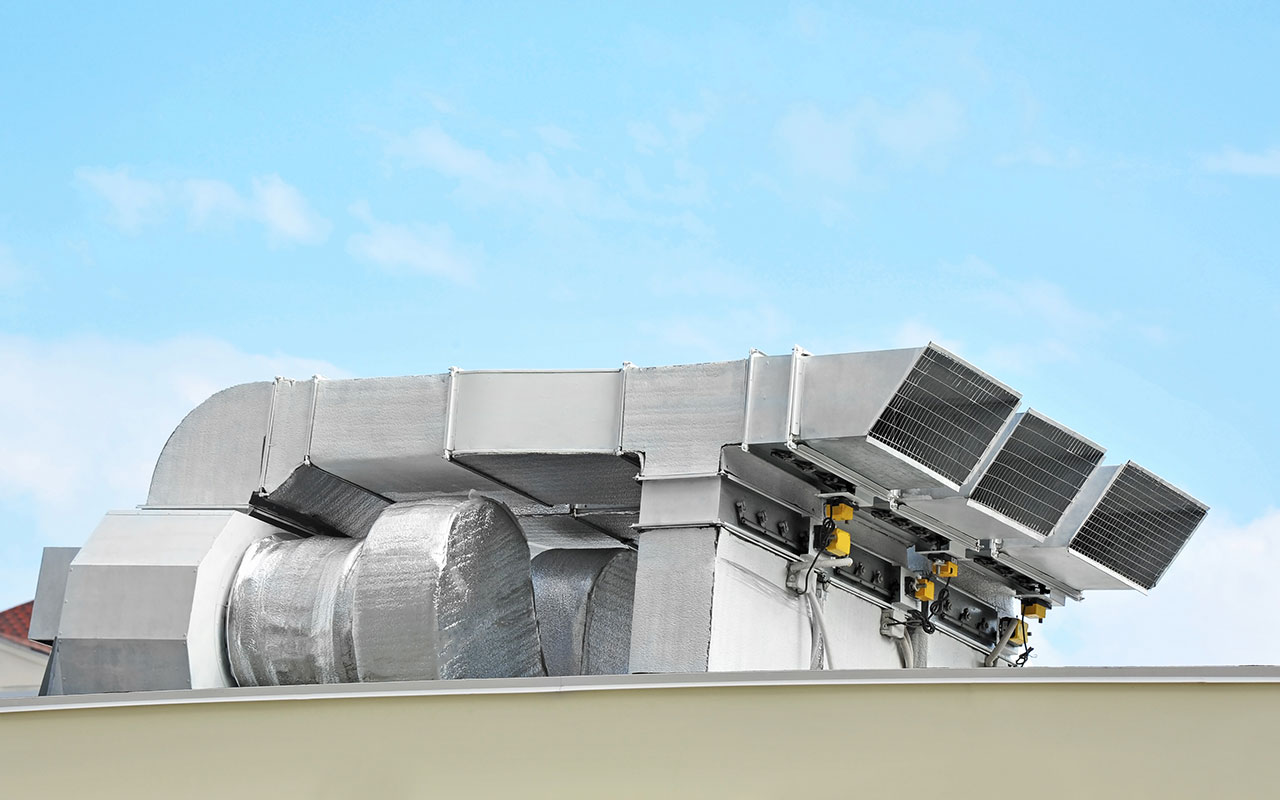

Applications:

- In humid and/or alcaline environments PH < 14

- Contact with cement

- Systems which house animals

- In chlorine environments

- Coastal areas

- Swimming pools

- In ammonia environments

- In chlorine environments (seaside, swimming pools)

- When anti-corrosion protection is strongly needed

- Instead of galvanized steel with high zinc coating

- Construction industry

- Use as pre-painted

- Industry and automotive industry

- For painted and non painted* applications

Technical supply terms:

| g/m² and μm coating on both sides | ||||||

| Zinc magnesium | ZM 70 | ZM 90 | ZM 120 | ZM 150 | ZM 275 | ZM 310* |

Weight of deposited alloy

Standard coatings (further coatings are possible pursuant to EN 10346 standard upon previous agreement with VoestAlpine)

Maximum thickness of base material is currently 2,00 mm

Maximum width 1500

EXAMPLES OF USE