Cold rolled steel

Cold-rolled steel with high yield strength for cold forming

Standard of reference UNI-EN 10268

Non-alloy cold-rolled steels with a thickness of less than 3 mm, intended for forming or drawing, suitable for surface coatings (phosphating, painting, electrolytic coating, dip galvanising).

Materials used in applications that require resistance, stiffness and ductility and improved superficial aspects due to the treatments described above. Fields of application: automotive industry, furniture, white goods, heating and ventilation, pipes and section bars, etc.

| DC01 | for profiling |

|---|---|

| DC03 | for light drawing |

| DC04 | for deep drawing |

| DC05 | for very deep drawing |

| DC06 | for extra deep drawing |

| DC07 | for super deep drawing |

Cold-rolled steel for enamelling

Standard of reference UNI-EN 10209

| DC01 EK | for profiling |

|---|---|

| DC04 EK | for deep drawing |

| DC06 EK | for very deep drawing |

| DC03 ED | for light drawing |

| DC04 ED | for deep drawing |

| DC06 ED | for very deep drawing |

STEELS FOR TRADITIONAL ENAMELLING

- DC01EK – DC04EK – DC06EK

- DC03ED – DC04ED – DC06ED titanium-alloyed decarbonised

STEELS FOR DIRECT ENAMELLING

- UNISMALT – SOLFER – SOLFER PLUS decarbonised open coil

- DC03ED – DC04ED – DC06ED decarbonised open coil

Before using the titanium alloyed decarbonised steels, it is essential to know the enamelling process in order to identify the most appropriate grade.

Cold-rolled steel for drawing and cold forming

Standard of reference UNI-EN 10268

High tensile steels with guaranteed minimum yield strength, which are excellent for welding and cold forming. Within this steel range, there are different grades depending on the final use, identified by the number that determines the minimum guaranteed yield strength.

The high mechanical characteristics and the good drawing grades allow to create cost-effective solutions for several parts or components requiring reduction in weight, thickness and overall dimensions, while leaving unchanged the resistance of parts or components.

Some examples of application can be: highway trailer trucks, buckets, large trucks, cranes, farm equipment, beams, welded tubes, profiles in general for scaffolds or shelves, containers, guide bars, street lamps. The regularity of spring back makes this steel suitable for all automated mass productions and also facilitates assembly.

- Bake-hardening steels (B)

- Re-phosphorised steels (P)

- Micro-alloyed and low-alloyed steels (LA)

- Interstitial-free steels (Y)

- Isotropic steels (I)

| Microalloys LA |

Bake-hardening B |

Interstial free Y |

Re-Phosphated P |

Isotropic I |

| — | HC180B | HC180Y | HC180P | — |

| — | HC220B | HC220Y | HC220P | HC220I |

| HC260LA | HC260B | HC260Y | HC260P | HC260I |

| HC300LA | HC300B | — | HC300P | HC300I |

| HC340LA | — | — | — | — |

| HC380LA | — | — | — | — |

| HC420LA | — | — | — | — |

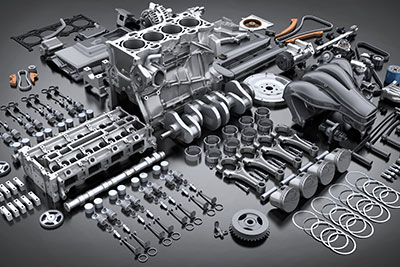

EXAPLES OF USE